> COMPANY > Product information

Product information

Arcyl?

| Ingredient | MMA (Methyl Methacrylate) |

|---|---|

| Specific gravity | 1.17~1.20 which is about 1/2 of inorganic glass, so a higher specific gravity results in a higher strain rate to have good mechanical and physical properties. |

| Optical property | The light penetration rate is 92~98% to have excellent transparency, and the spectrum beam penetration rate shows granularity at 2,500A UV wavelength to penetrate UV, which is far more excellent than inorganic glass. In the visible light region, this shows no absorption heat, and the visible light penetration rate is 93%, and the 7% is the surface reflective index. The refractive index is 1.49 for sodium D lines before noon, which is a little lower than 1.52 of colorless glass. |

| Thermal machinability | The the main ingredient of acryl is MMA (Methyl Methacrylate), whose thermal plasticity temperature is 70~110℃, so bending or molding even at 95~110℃ causes no bleaching or crazing. |

| Nontoxic/harmless(human) | Today is an era where humans are surrounded by environmental contaminations due to toxic industrial materials, but only acryl is nontoxic to be widely used as essential materials for humans directly and indirectly such as dishes, food vessels, false teeth, artificial eyes, artificial bones, incubators, etc. |

| Colorless and transparent | The colorless and transparent acryl is as highly transparent as through which objects can be seen from a 2m thickness like crystal to be used for windows of aircraft or lighting from long time and far distance needing high class as well as thickness. |

| Variety of colors | Acryl can be freely colored with pigments or paints as much as desired by the user, and can be clearly colored as variously as you want. Acryl has an advantage of being not discolored even during machining for molding. |

| Matt acryl | The planar-embossed acryl has a mild gloss to be used for interior and special uses. |

| Strength and weight | The impact strength of acryl is 4-17 times that of reinforced glass to be widely used for places requiring safety such as windshields of aircraft, and the weight of acryl is only a half of glass. Acryl has excellent thermal machinability compared to its high strength to be used for false teeth, etc. However, acryl has a disadvantage of having weaker durability than glass. |

| Excellent surface gloss | The surface of acryl has high gloss and beauty to be widely used in various industrial fields as the best raw material such as interior, accessory, display, etc. |

| Weatherproof | Acryl has an excellent weatherproofing advantage of being not easily deteriorated in physical properties such as discoloring, surface state, strength, etc. due to its strong resistance to long time and weather change to be used for aircraft windshields, outdoor signboards, traffic signboards, car lamp covers and others. |

| Moldability | Acryl can be bended and molded into simply curved surfaces, multiply curved surfaces, boxes and other complicated shapes via pressurized molding, injection molding or drawing almost without discoloration or deterioration due to temperature to cause no quality change. |

| Machinability | Acryl can be freely and variously machined by machines such as drilling, cutting, boring, sculpturing, grinding, bonding, painting, dyeing and metal overlapping as well as molding, and even grinding of the cut parts can maintain its own gloss and surface treatment to be a pride compared to other industrial raw materials. There are 30,000 kinds of machining in general. |

| Use | This is an industrial material for various fields needed for upgrading of commodities due to its easy machinability according to design such as aircraft, automobiles, electric cars, trains, lighting, signboards, soundproof walls, safety mirrors, sun visors, stationery, skylights, indoor ceilings, street lamps, advertisements, architecture, doors, machine gauge panels, letter panels, watches, lenses, cosmetics, promotions, interior, miscellaneous goods, cabinets, showcases, display, large aquaria, submarine tunnels and various models. |

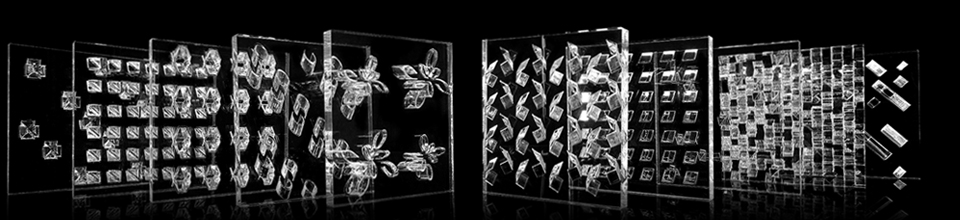

New transparent acrylic

|

Multiglass is a plastic used much in replacement of glass, which is produced in a planar, rodlike or tubular type variously according to its color, transparency and surface texture. There are colored transparent plates and transparent plates of acryl; the interior and display use thin plates and the household furniture uses thick plates in general. In addition, acryl can be variously colored with pigments, is not discolored during molding or general machining, has excellent durability, weatherproof and machinability, and is not discolored or deformed to be eternal. Recently, static electricity-free plates, hard coated plates and optical-catalyst coated plates are being produced by complementing the disadvantages of static electricity generation or surface flaw occurrence. |

|---|---|

| Feature |

|

| Use | Showcase, cigarette case, cosmetics case, game machine acryl fabrication, aquarium fabrication, special machining, food and medical tools(incubator), various moldings, department store display article, industrial equipment, etc. |

Pastel acryl

|

This is a product of the same material as acryl whose rear surface is treated with planar back light, producing mild gloss to direct a high-class image. |

|---|---|

| Feature |

- Beautiful color of pastel tone - Various colors for wide selections - Mixed colors and overlapped colors using lighting - Recycling of resources - Easy molding, bending and bonding |

Transparent color acryl

|

|

|---|---|

| Feature |

1. Easy light shielding and color shielding 2. Free selection of colors 3. Splendid and simple articles when finished |

| Use | Medical goods, food, light shielding, industrial equipment cover, food sanitation cover, etc. |

Polycarbonate

|

The transparent soundproof wall can provide the surrounding pleasant natural scenery to residents and drivers around the road and secure a broad vision to reduce psychologically-sealed feelings, and can be variously fabricated and installed according to the road and surrounding conditions. | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Feature |

1. Sound insulation : Good insulation and reflection of sounds using transparent plates 2. Constructability : Bonding or multi-constructing of other materials 3. Beauty : Beautiful structure and balanced stability in a form according to the surroundings |

||||||||

| Application |

Express roadside, roadside, railwayside, elevated roadside, apartment boundary, workplace boundary, etc.

|

||||||||

| Soundproof wall use |

|

Hanji acryl

| Hanji(Korean handmade paper) is inserted between acryl and acryl to show various patterns and single color. This is a product much used at traditional restaurants or Japanese food stores for indoor interior. | |

| Use |

Mostly used to direct an atmosphere for lighting boxes such as interior, indoor decoration, Japanese restaurants, etc.

|

Laminated acryl

|

The laminated acryl is manufactured by laminating marble and wood-pattern paper. |

|---|---|

| Feature |

The laminated acryl can direct the unique pattern and atmosphere of marble or wood and can be used semi-eternally. This can also be used in place of glass because it is not easily broken. |

| 용도 | This can be used for architectural construction, interior materials, signboard materials, display and show windows, and is being used at many places such as Korean/Japanese/Chinese restaurants, hotels apartments, wedding halls, country houses, temples, etc. |

Arcyl color code